After our many trips to Sutter Creek, I finally paid attention to the signs and discovered the Knight Foundry. Turns out that once a month the foundry have an open house and tours. I learned some pretty cool things on this tour.

This foundry was built and operated until the '90's as a water powered shop. This means that all the lathes, drills, and other equipment were operated by using flowing water to turn a water motor and this to turn a shaft. On the shaft, each large device has a series of pulleys onto which a leather belt can be slid and connect the machine tool to the power.

In the '90's the place was bought and not used for a decade or more and asa result, the water rights were lost. Until a valiant group of volunteers are able to find a way to resume water usage, it is now operated with electric motors. But the changes are minimal and it still operates as always.

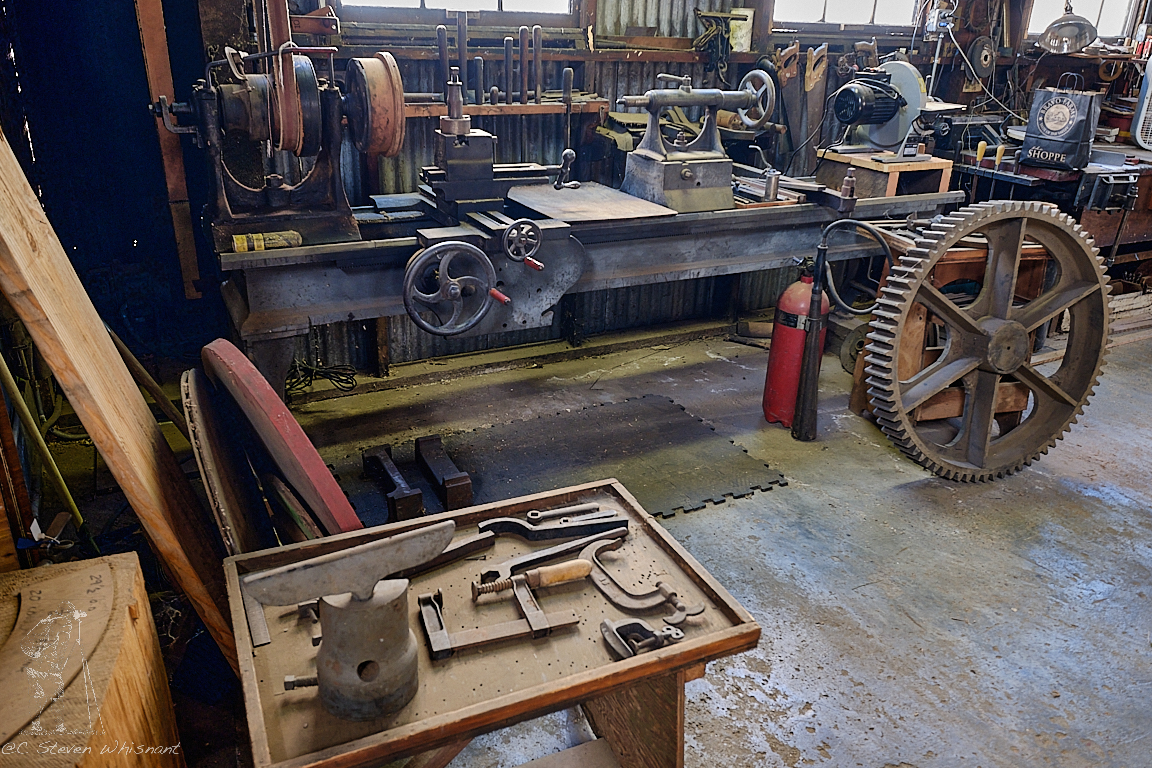

What you see above and in the video below is a very large lathe used to turn large wheels and gears. It is, as I said, run now by an electric motor but used to run on water. I find this really amazing. It would never occur to me try powering this by water.

Next on the tour is the shop office. This place was established in 1873 and operated for 123 years. So, it is not unusual to see that there is a phone on the desk.

In the main shop is a world of delights. The portion of the facility shown below is the pattern shop. Here, wooden forms are made that are used to make the spaces in damp sand that forms the moulds for the pieces to be made. the moulds must be made to avoid places where cracks and weak points result. To achieve this, all corners are rounded. More importantly, the mould be made in such a way that it can be removed from the sand without moving any of the sand and disturbing the ability to make the piece.

If that sounds hard to pull off, there is also the problem of shrinkage. Metal shrinks as it cools. This means that the pattern maker is assembling a wooden pattern to make a void in the wet sand that will hold enough hot metal in the right places so that when it cools, it is the right size. Now that requires talent and skill!

No comments:

Post a Comment

We enjoy hearing from our readers.